A Marriage Between Solar and Forest: Japan Promotes Wooden PV Racking Systems

— In the midst of the rapid growth in its solar photovoltaic (PV) market, Japan is looking into its local resources — forests — to provide racking for PV systems. Several firms in Japan are turning domestic cypress or cedar trees into PV racks, which are traditionally made of metal such as aluminum and steel. A 150-kW PV system owner in Mie prefecture stated that it came naturally to choose wood as racking for environmentally friendly solar energy. The company used cedar wood, which was harvested locally.

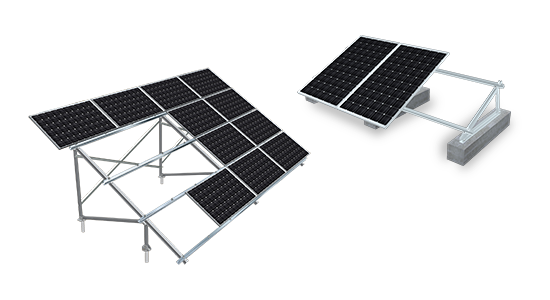

Solar PV with wooden racking. Credit: Dainihon Wood-Preserving Co.

The strategy behind the marriage between solar and forest works perfectly for Japan. Both resources are abundant locally, and this means that it helps to stimulate local economies and reduce imports.

Japan is poor in natural resources and relies heavily on fossil fuel imports, thus solar is a prime choice to help support its energy independence. The story is slightly different, however, for wood. Japan is blessed with vast forests, but the domestic market is currently saturated with low-cost, imported timber, reducing the nation’s self-sufficiency for lumber from 98 percent in 1950 to 26 percent in 2011, according to the Japan Forestry Agency.

Japanese Government Promotes Usage of Thinned Wood

Forests cover about 70 percent of the land area in Japan. Of the total forestland, about 60 percent is natural and the remaining 40 percent is plantation forest, planted after World War II to meet the demand for timber as construction material. While Japanese cedar and cypress trees planted post-war were still growing, the nation’s demand for wood during the rapid economic growth was satisfied by imports.

When the planted trees were ready for harvest, the domestic wood was not priced competitively compared with imported woods, making domestic forestry unprofitable and leaving the domestic trees unmanaged. This has led to the deterioration of many plantation forests.

To revitalize the domestic forests, the federal government enacted the Forest and Forestry Basic Law in 2001, designed to promote thinning and coordinate and consolidation of forestry management among groups of small forest owners. Thinning is an effective way to promote timber growth and restore forest health, by removing slower growing tress to provide more space for other trees to grow bigger and healthier.

The Forestry Agency specifically promotes thinning activities and usage of thinned wood with subsidies under the Thinning Promotion Special Law. Between 2007 and 2011, 3.8 million hectares of forests were thinned in Japan.

“We developed (wooden PV racking) in order to make use of and expand usage of local woods. That is our company mission,” said Naomi Urakami, a representative of Sun Forest Co., which started marketing PV racks made of thinned wood in 2013. The company is a wholly owned subsidiary of Forest Owners Cooperative Associations representing Hyogo prefecture.

PV systems with wooden racking. Credit: Sun Forest

Urakami continued, “Creating wooden PV racks stimulates usage of the domestic woods. And utilizing the domestic woods promotes proper forest management.” The company currently utilizes thinned Japanese cedar trees for wooden racks. The largest system the company developed so far is a 5-MW system in Hyogo prefecture.

Dainihon Wood-Preserving Co., a firm specializing in wood pressure-treatment for the last 90 years in Kagawa Prefecture, has expanded its business knowledge into PV wooden rack systems. “Woods match much better to the environmentally friendly solar energy than steel,” said Dai Ishiguro, a company representative.

The company also uses thinned wood, which is pressure-treated with copper azole, water-borne preservatives, ensuring a long service life in a wide range of conditions and assuring performance in sensitive environments. Field simulations conducted by several research firms concluded that the company’s pressure-treated wood lasts at least 20 years, which is the duration of the current feed-in tariff (FIT) policy. “We chose thinned woods to promote local production for local consumption,” said Ishiguro.

PV system with pressure-treated wooden racking. Credit Dainihon Wood-Preserving Co.

Wood vs. Metal

Wooden racking systems offer a number of benefits over metal racks. Wood can prevent PV systems from losing efficiency due to rising temperatures due to their lower heat conductivity. Another benefit is that wood will not corrode or rust. Since Japan is an island country surrounded by oceans and seas, salt-water droplets in the air can corrode many newly developed PV racking systems over time.

Kanematsu Nissan Norin Corp., another wooden PV rack maker, lists “ease of installation” as another benefit. The company utilizes the traditional mortise-and-tenon joint in woodworking, thus installers can assemble the racks easily without nails. And compared to steel racks, wooden racks are much lighter and easier for workers to carry and construct. The company stated that it would take 21 minutes for 2 people to assemble a wooden racking system for a 0.9-kW PV system.

The company also stated that its wooden racks have preservative and protective treatments, making the life of the wooden racks about 30 years.

Another benefit to using wood as PV racking is that the wood can be used further, after its life as PV racking. Fujita Kensetsu Kougyou, a construction company in Fukushima, developed three PV systems with wooden racks made of thinned Japanese cypress. The company also chose wood to promote local production for local consumption and to revitalize the forest industry in Fukushima. The company decided not to apply preservative treatments to the wood and at the end of its useful life, these wooden PV racks will be recycled as biomass energy to contribute to the nation’s energy needs. Sun Forest and Sumitomo Forestry are also planning to recycle used wood as biomass after its 20-year lifespan.

Though they have many environmental benefits, wooden racking systems are a bit more costly. For a 50-kW system, the average cost of a wooden rack is ¥35,000/kW (US $325/kW), compared to ¥20,000/kW (US $127/kW) for steel and ¥30,000/kW (US $281/kW) for aluminum, according to Ishiguro at Dainihon Wood-Preserving Co. “Driven steel piles without concrete footings is becoming more common in Japan. However, our products require solid concrete footing to anchor the rack to the ground. This can add extra cost (to wood over steel or aluminum),” said Ishiguro.

“Considering the cost of dismantling, our products are cost competitive [to racks made of steel],” said Hiroki Ohnishi, PR manager of Sumitomo Forestry Co., Ltd., which sells lumber and wood-related construction materials and constructs and markets wooden houses and other wood-based products. “The customer’s choice (over type of racks) boils down to a priority — cost or environment-friendliness,” said Ohnish.

At the end of April, Japan had over 68 GW worth of reserved PV capacity under the FIT program. This can be translated into a potentially large demand for wood in Japan. The government stated, “Wood use contributes to the development of comfortable living condition, promotion of local economy, and mitigation of global warming.” Let’s hope the marriage between solar and wood will have an important role in boosting the domestic economy while creating a sustainable, clean environment.